Reliable quality, best price, easy operation and maintenance If you have less different cartons, and procurement amount is limited, FX-50B carton sealer is a good choice. If you have many different cartons, and don’t need flap them, FX-50A case sealer is applicable, automatic adjustment without flaps folding.

#OPP HOT LABELLER MANUAL#

If you have less different cartons, and the carton needs to be folded, FX-50F carton sealing machine is suitable, automatic flap folding, manual adjustment.FX-50F carton sealer can be used alone, also connect with other machine for production line, for example case packer. And this automatic carton sealing machine can help save much manpower, also easy to operate and maintenance.FX-50 carton sealer can be used alone, also connect with other machine for production line, for example case packer. capacity requirement, we will match solution as it.If you have many different sizes of carton, FX-50 carton sealer will be your ideal choice, it can detect different carton size, then adjust itself automatically to adapt to each carton.

#OPP HOT LABELLER HOW TO#

Engineer install and train client how to use and maintain machineĢ. When the temperature can not meet the equipment requirement, the machine will stop to against bad products produceġ.

When the vacuum can not meet the equipment requirement ,the machine will stop to against bad products produce When the pressure can not meet the equipment requirement ,the machine will stop to against bad products produce The machine will restart automatically as soon as the bottles have been put that will facilitate on-line production

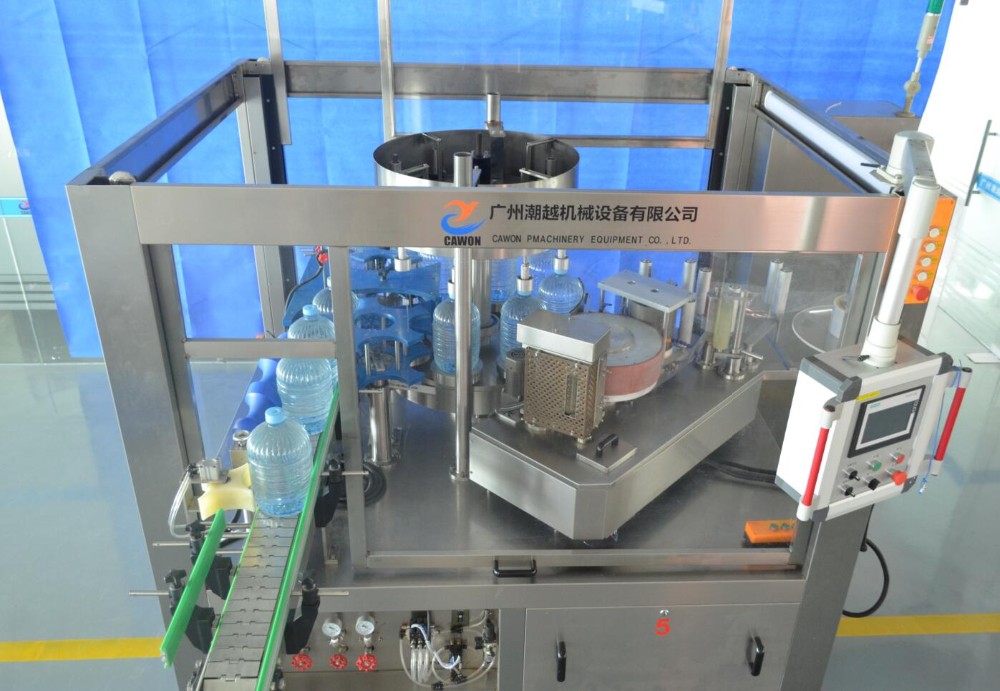

When lack of the bottle the machine will stop and make an alarm. Set an alarm to remind the operator to change the label when the label will be use out In order to keep the operator safety ,when the machine is running please close the protective doors Hot melt glue supply system(German SEIMEC control system) ensures the accuracy and uniformity of gluing High speed servo opp label supply system (drive by servo-motor)Īdjust by double coordinate section guide rail Mechanical pre-location, using the camwheel institution to planish the bottle for label positioningĬontainers are pick up by rotary wheel ,labeling during the rotation. With worm sub bottle institution and starwheel position feeding institution to ensure the accuracy and stability of loading TRANSTECNO motor 2.2Kw (with deceleration by TRANSTECNO) Italy FLEXON LF820-K325 industrial nylon chain plate conveyor TRANSTECNO motor 750W(with deceleration by TRANSTECNO ), inverter speed control Japan SUNX Detection Sensor for coating adhesive Gluing of the trailing edge ensures proper bonding. As the container is rotated during label transfer, labels are applied tightly. This glue strip ensures an exact label positioning and a positive bond. The label with the glue strip on its leading edge is transferred to the container.

Two narrow strips of hot melt glue the labels together, which are applied by a heated glue roller to the leading and trailing label edges. In the cutting unit, the labels are precisely cut while a PLC command and servo-motor provide an exact cut-off point. A standard threading unit ensures optimal film feed. The speed of the feed roller is adjusted to the required label length for continuous web tension. The container rotation begins when they are positioned between container plates and centering bells. The containers are picked up by the infeed starwheel and transferred to the container table. Suitable for round or square containers made of plastic, metal, glassīopp ,paper-plastic composite film ,paper label Glue at both ends of each label with hot melt 3650mm×1700mmX 2010mm(can be adjusted by customer requirements)

0 kommentar(er)

0 kommentar(er)